TECHNICAL INFORMATION

Duracorr is a low-cost, 12% chromium, molybdenum based, stainless steel manufactured in the United States by ArcelorMittal USA

Duracorr, UNS designation S41003, is governed by the specification ASTM A1010 and is listed as an approved material in ASME section IX.

Duracorr has a fine-grained microstructure of ferrite and tempered martensite which supports ease of fabrication and processing. With its specifically designed chemistry, the Duracorr product promotes weldability and offers exceptional mechanical properties that create a sense of confidence for end users.

Documents

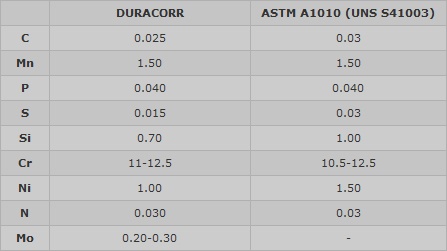

Duracorr has low carbon content, up to 12.5% chromium, as well as the addition of molybdenum which stabilizes and ensures desired physicals for this product.

Chemical Composition (in weight %)

Duracorr is strong, tough, corrosion resistant, formable and weldable. The physical characteristics of Duracorr make this material a prime candidate for numerous oil and gas applications involving pipe and plate.

Duracorr is available in grade 40 (40ksi yield), grade 50 (50ksi yield), and grade 300 (100-110 ksi yield.) Information below is based on Duracorr Grade 50.

Yield Strength:

- 50 ksi minimum (345 MPa), 58 ksi typical (399 MPa)

Ultimate Tensile Strength:

- 70 ksi minimum (483 MPa), 77 ksi typical (531 MPa)

Hardness:

- 223 Brinnell maximum (97 Rb), 160 Brinnell typical (84 Rb)

Elongation (in 2 inches <50mm>):

- 18 % minimum, 33 % average

Charpy-V-Notch Impact:

- > 30 ft-lbs (41joules) at -40°F / -40°C. Duracorr exhibits excellent charpy values in the parent material, weld, and heat affected zone that all surpass the respective requirements in API, ASME and ASTM specifications.

Duracorr was designed with welding in mind. The fine grained microstructure of ferrite and tempered martensite makes Duracorr readily weldable and form-able.

Duracorr can be welded to itself, carbon steels, and other stainless steels using various methods such as flux-cored arc (FCAW), gas tungsten arc (GTAW), gas metal arc (GMAW), and shielded metal arc (SMAW).

Austenitic filler metals 309L, 308L and 316L can be used for arc welding Duracorr; however type 309L is recommended for most applications.

Duracorr pipe is currently manufactured by submerged arc welding. Autogenous weld methods of producing Duracorr pipe are also available and are currently under improvement.